The production process

Process is time consuming, but the results are worth it

- Washing

- Conditioning and hydrophobic treatment

- Drying

- Sorting

- De-dusting

Washing – is carried out on high-tech equipment in several stages with hot water using special detergents for dirt and grease extracting. The purpose of washing is to get rid of grease, mineral and protein contamination and prepare feathers for further sorting and processing.

Conditioning – rinsing with special anti-static and softening agents. The process is intended to make anti-static effect and helps in further process of sorting feathers. Hydrophobic treatment helps to protect feathers from moisture. We make hydrophobic treatment of down and feather for the use in sleeping bags on our clients’ request.

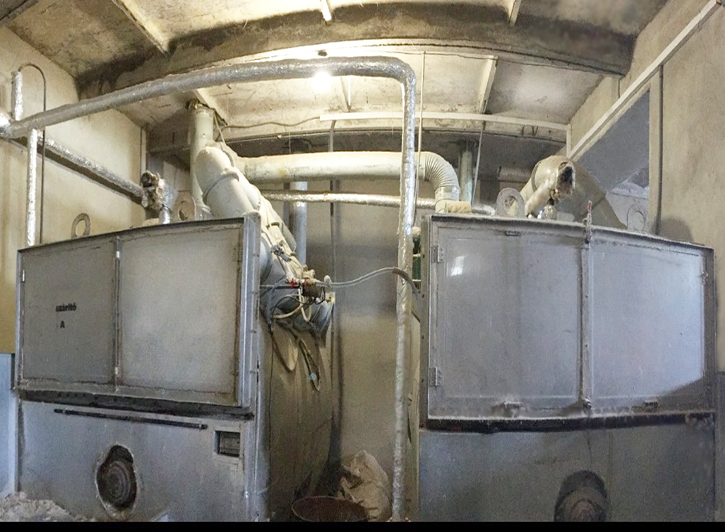

Sorting – is a process that separates feathers and down in special chambers. Feathers are sorted into different quality. To sort feathers we use four chamber sorting machines that separate material into five different qualities. Material is sorted by specific gravity in a stream of air created by a special fan that goes uphill.

Drying – is made with the hot air of 120 °С for the purpose of drying and sterilizing. Before drying feathers we make its mechanical dehydration. For this purpose we use centrifuge. Then the drying is done at higher temperature. This eliminates bacteria and feathers are ready for further processing.

De-dusting – coarse and fine waist removing.

Packaging in polypropylene bags is the final stage. We use mechanical press to reduce the volume and size of the package.